Oil Sealed High Vacuum Pumps

Oil Sealed High Vacuum Pumps Specification

- Equipment Type

- High Vacuum Pump

- Material

- Cast Iron

- Processing Type

- Vacuum Pumping

- Condition

- New

- Technology

- Oil Sealed Rotary Vane

- Dimension (L*W*H)

- Varies By Model

- Power Mode

- Electric

- Power Consumption

- 0.25 to 10 HP (Depending on Model)

- Pressure Output

- Up to 0.05 mm Hg (50 Microns)

- Application

- Industrial, Laboratory, Pharmaceutical, Chemical and Food Processing

- Coating Type

- Powder Coated

- Accessories

- Oil Mist Filter, Inlet Filter, Exhaust Filter

Oil Sealed High Vacuum Pumps Trade Information

- Payment Terms

- Others

- Delivery Time

- Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Certifications

- No

About Oil Sealed High Vacuum Pumps

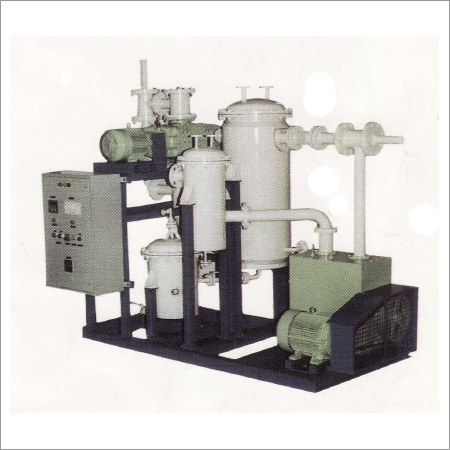

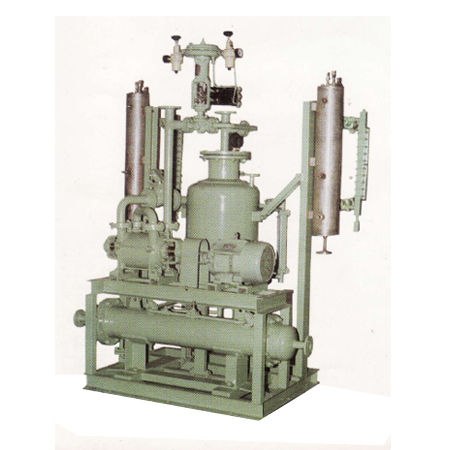

Oil Sealed High Vacuum Pumps (Industrial Models)

With the assistance of our experienced engineers and technicians, we are offering our clients a broad range of Oil Sealed High Vacuum Pumps (Industrial Models) which is most appropriate for distillation, drying, bright anealing, evacuation of large systems and impregnation. Extensively demanded in varied industries, these pumps are reckoned for their reliable operation, easy installation, durable finish standards and resistance to corrosion. These high performing Oil Sealed High Vacuum Pumps (Industrial Models)are offered by us at cost effective prices.

Specifications:

- Capacity : 325 to 10000 lit/min

- Ult. Vacuum : Upto 0.005 torr

Reliable Oil Sealed Rotary Vane Technology

Our high vacuum pumps utilize advanced oil sealed rotary vane mechanisms, ensuring consistent and efficient vacuum performance. This technology is ideal for applications where stable and high vacuum levels are essential, making the equipment reliable and durable even in challenging industrial and laboratory settings.

Versatile Applications for Multiple Industries

These vacuum pumps are crafted to serve a broad spectrum of industries, from pharmaceuticals and laboratories to food processing and chemical manufacturing. Their robust construction from cast iron and the inclusion of specialized filters allow them to handle demanding processes seamlessly, ensuring compliance with industry standards.

FAQs of Oil Sealed High Vacuum Pumps:

Q: How does an oil sealed rotary vane high vacuum pump operate?

A: Oil sealed rotary vane vacuum pumps function by using rotating vanes inside a sealed chamber, where oil acts as a sealant and lubricant. This setup allows the pump to create and maintain high vacuum levels by efficiently removing air and gases from the system.Q: What advantages does cast iron construction offer for vacuum pumps?

A: Cast iron construction provides the pumps with exceptional strength, durability, and resistance to wear and corrosion. This ensures a long operational lifespan, even in harsh industrial and chemical processing environments.Q: When should oil sealed high vacuum pumps be used in laboratory or pharmaceutical applications?

A: These pumps are ideal for laboratory or pharmaceutical applications requiring a clean, stable, and deep vacuum, such as distillation, freeze drying, and filtration processes. Their high efficiency and included filtration accessories help maintain contaminant-free environments.Q: Where can these high vacuum pumps be installed or used effectively?

A: Our oil sealed high vacuum pumps can be effectively installed wherever high vacuum is essential, including laboratories, pharmaceutical production units, chemical plants, and food processing lines. Their design accommodates varied space and process requirements.Q: What maintenance is required for oil sealed rotary vane vacuum pumps?

A: Regular maintenance involves changing the oil, checking for leaks, and cleaning or replacing inlet, exhaust, and oil mist filters. Proper maintenance ensures consistent performance and extends the service life of the pump.Q: What are the primary benefits of using filters such as oil mist, inlet, and exhaust filters?

A: These filters help prevent oil vapor emissions, protect the internal mechanism from debris, and ensure a clean exhaust, thus improving the operational safety, longevity, and cleanliness of the pumping process.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vacuum Pumps Category

Diaphragm Type Vacuum Pumps

Material : Other, Aluminum Alloy and Engineering Plastic

Condition : New

Processing Type : Other, Vacuum Pump

Dimension (L*W*H) : 210 x 150 x 210 mm

Application : Laboratory, Filtration, Medical, Chemical Processing

Power Mode : Electric

Mechanical Booster Vacuum Systems

Material : Other, Mild Steel

Condition : New

Processing Type : Standard

Dimension (L*W*H) : Customizable as per requirement

Application : Industrial, Chemical, Pharmaceutical, Food Processing, Vacuum Drying, Distillation, Dehydration

Power Mode : Electric

Solvent Recovery Unit

Material : Other, Stainless Steel

Condition : New

Processing Type : Other, Solvent Recovery

Dimension (L*W*H) : 1200 mm x 850 mm x 2000 mm

Application : Solvent purification and distillation in chemical, pharmaceutical, and paint industries

Power Mode : Electric

Solvent Recovery Plant

Material : Other, Stainless Steel

Condition : New

Processing Type : Other, Batch/Continuous

Dimension (L*W*H) : 3300 mm x 1800 mm x 2200 mm

Application : Industrial solvent recovery, chemical, pharmaceutical, paint, ink, and coating industries

Power Mode : Electric

Unit No.1

Plot No. 7, Udyog Nagar, S.V.Road,

Goregaon (West), Mumbai-400 062.

Maharashtra. INDIA

Phone : 28740513

Unit No. 2

Plot No. A-316, Wagle Industrial Estate,

Road No. 22 Thane-400 604.

Maharashtra. INDIA

Tele : 25821773

Telefax : 25828006

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry