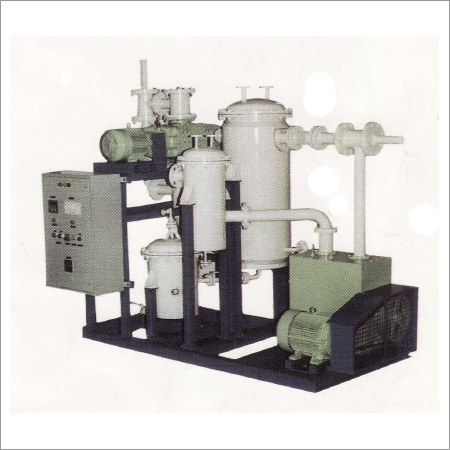

Oil Sealed High Vacuum Pump

Oil Sealed High Vacuum Pump Specification

- Equipment Type

- High Vacuum Pump

- Material

- Cast Iron

- Processing Type

- Vacuum Generation

- Condition

- New

- Technology

- Oil Sealed Rotary Vane

- Dimension (L*W*H)

- Varies by Model (e.g., 450 x 180 x 250 mm)

- Power Mode

- Electric

- Voltage

- 220V/380V, 50/60 Hz

- Power Consumption

- 0.5 kW 5 kW

- Pressure Output

- Up to 0.05 mbar

- Application

- Laboratory, Industrial, Research, Pharmaceutical, Chemical Processing

- Coating Type

- Anti-Corrosive Coating

- Accessories

- Inlet Filter, Oil Mist Filter, Exhaust Valve

Oil Sealed High Vacuum Pump Trade Information

- Minimum Order Quantity

- 1 Nos

- Payment Terms

- [, ]

- Supply Ability

- 1 Nos Per Week

- Packaging Details

- wooden box packing

- Main Export Market(s)

- [, ]

- Main Domestic Market

- A, l, , a, ', l, d, i, ], [, ', I, n

About Oil Sealed High Vacuum Pump

Robust and Reliable Performance

Crafted for demanding environments, this oil-sealed rotary vane pump offers powerful vacuum capability and consistent output. The cast iron construction and anti-corrosive coating guarantee durability, while high vacuum pump oil ensures optimal lubrication and extended maintenance cycles. Users can rely on this technology for continuous, stable operation across a broad range of applications.

Versatile Applications and Compatibility

Ideal for laboratories, industrial setups, research facilities, pharmaceuticals, and chemical processing, this high vacuum pump adapts seamlessly. Equipped with standard BSP/NPT port sizes and a range of motor and voltage options, it easily integrates with existing systems, providing flexibility for both exporters and domestic users alike.

FAQs of Oil Sealed High Vacuum Pump:

Q: How does the oil sealed high vacuum pump operate and generate vacuum?

A: The oil sealed high vacuum pump uses rotary vane technology, where vanes trap air and oil lubricates the moving parts, creating a tight seal. As the vanes rotate, air is compressed and expelled, resulting in the creation of a high vacuum, capable of reaching an ultimate pressure of 5 x 10^-2 mbar.Q: What maintenance is required for this vacuum pump and how often should the oil be changed?

A: Routine maintenance includes checking oil levels and quality, cleaning the inlet filter, and inspecting seals. The oil should be changed based on usage intensity or whenever it appears contaminatedtypically every 500-1,000 operating hours for optimal performance.Q: Where can this oil sealed high vacuum pump be used effectively?

A: This pump is designed for diverse environments, such as laboratories, industrial workspaces, research institutions, and pharmaceutical or chemical processing plants, due to its robust construction and reliable vacuum performance.Q: What are the key benefits of using an oil sealed high vacuum pump over dry pumps?

A: Oil sealed high vacuum pumps provide higher vacuum levels, quieter operation ( 68 dB), improved cooling, and reduced wear on moving parts, resulting in longer service life and lower overall maintenance compared to dry pumps.Q: How is the pump installed and mounted for optimal performance?

A: The pump is base mounted for stability, and should be set on a level surface with adequate airflow for efficient air cooling. Standard BSP/NPT ports allow easy attachment to existing vacuum lines, while single or three-phase motors accommodate various electrical setups.Q: When is it necessary to use accessories like inlet filter, oil mist filter, and exhaust valve?

A: These accessories are essential during regular operation to prevent contaminants entering the pump, control oil mist emissions, and manage exhaust flow, thereby extending pump life and maintaining a cleaner work environment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vacuum Pumps Category

Oil Sealed Vacuum Pumps

Material : Other, Cast Iron / Mild Steel

Power Mode : Electric

Condition : New

Pressure Output : Up to 0.005 Torr

Processing Type : Standard

Voltage : 220V / 415V

Monoblock Water Ring Vacuum Pumps

Material : Other, Cast Iron

Power Mode : Electric

Condition : New

Pressure Output : Up to 700 mm Hg

Processing Type : Other, Monoblock

Voltage : 220/380 V

Mechanical Booster Vacuum Systems

Material : Other, Mild Steel

Power Mode : Electric

Condition : New

Pressure Output : Up to 0.001 mbar

Processing Type : Standard

Voltage : 380V 440V

Liquid Ring Vacuum Pumping System

Material : Other, Stainless Steel / Cast Iron / Bronze (as per requirement)

Power Mode : Electric

Condition : New

Pressure Output : Up to 33 mbar (abs)

Processing Type : Other, Vacuum Generation

Voltage : 220 V / 380 V / 415 V, 50 Hz / 60 Hz

Unit No.1

Plot No. 7, Udyog Nagar, S.V.Road,

Goregaon (West), Mumbai-400 062.

Maharashtra. INDIA

Phone : 28740513

Unit No. 2

Plot No. A-316, Wagle Industrial Estate,

Road No. 22 Thane-400 604.

Maharashtra. INDIA

Tele : 25821773

Telefax : 25828006

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry