Liquid Ring Vacuum Pumping System

Liquid Ring Vacuum Pumping System Specification

- Equipment Type

- Vacuum Pumping System

- Material

- Stainless Steel / Cast Iron / Bronze (as per requirement)

- Processing Type

- Vacuum Generation

- Condition

- New

- Technology

- Liquid Ring

- Power Mode

- Electric

- Voltage

- 220 V / 380 V / 415 V, 50 Hz / 60 Hz

- Power Consumption

- Varies by Model (typically 2 kW 75 kW)

- Pressure Output

- Up to 33 mbar (abs)

- Application

- Chemical, Pharmaceutical, Food Processing, Power Generation, Petrochemical, Distillation, Evacuation, Filtration

Liquid Ring Vacuum Pumping System Trade Information

- Payment Terms

- Others

- Delivery Time

- Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Certifications

- No

About Liquid Ring Vacuum Pumping System

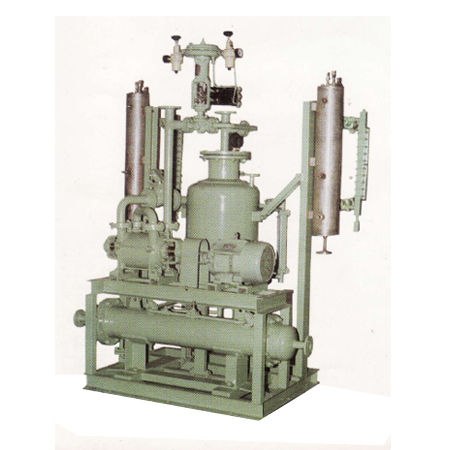

Liquid Ring Vacuum Pumping System

From the inception to completion of manufacturing task we ensure quality in providing exquisite gamut of Liquid Ring Vacuum Pumping System. Highly cost effective this pumping system gives maximum vacuum with less maintenance and high power efficiency due to which it is widely accredited by our precious customers. Liquid Ring Vacuum Pumping System is broadly utilized in solvent recovery and fractional distillation. The array of pumping system offered by us is tested under the supervision of our team of experts.

Specifications:-

Vacuum : 30 torr to 100 torr

Versatility in Applications

This vacuum pumping system adapts to a broad spectrum of industrial processes, such as distillation, filtration, and evacuation. Its flexible material optionsstainless steel, cast iron, or bronzeallow for compatibility with aggressive chemicals or hygienic food and pharmaceutical environments, ensuring reliability across applications.

Optimized Performance and Efficiency

Designed for power efficiency, these vacuum systems are available in models ranging from 2 kW to 75 kW, adjusting to your process needs. The liquid ring technology delivers reliable vacuum up to 33 mbar (abs), essential for complex operations in chemical and power generation industries, while minimizing operational costs.

Reliable Quality for Demanding Environments

Manufactured to withstand demanding operational conditions, our vacuum systems offer long-lasting durability and require minimal maintenance. As both supplier and manufacturer in India, we deliver rigorous quality assurance and customizable features to meet the precise specifications of critical industrial sectors.

FAQs of Liquid Ring Vacuum Pumping System:

Q: How does a liquid ring vacuum pumping system operate in industrial settings?

A: A liquid ring vacuum pumping system uses a rotating impeller within a liquid-filled casing to create a vacuum, efficiently evacuating gases from processes like distillation, filtration, and chemical reactions in various industries.Q: What materials are available for your vacuum pumping systems, and why choose them?

A: Our systems can be constructed from stainless steel, cast iron, or bronze depending on application requirements. Stainless steel is ideal for corrosive or hygienic environments (food and pharma), while cast iron and bronze are suited for general industry and specific chemical compatibility.Q: When should I use a liquid ring vacuum pump over a different vacuum technology?

A: Liquid ring vacuum pumps are preferred when dealing with wet gases, high condensation loads, or applications needing stable operation under varying process loadscommon in chemical, pharmaceutical, and food processing industries.Q: Where can these vacuum pumping systems be installed?

A: These systems are suitable for installation in chemical plants, pharmaceutical manufacturing units, food processing facilities, power generation plants, and petrochemical refineries. Their robust design allows deployment in both new and existing industrial setups.Q: What is the typical process for installing and starting up the system?

A: Installation involves positioning the pump system according to facility layout, connecting to the appropriate electrical supply (220V/380V/415V, 50/60 Hz), and ensuring correct piping and liquid ring fluid supply. Startup includes system checks and calibration as per operational guidelines.Q: How can users benefit from using a liquid ring vacuum pump system?

A: Users gain from high reliability, simple operation, low maintenance, and suitability for handling wet or contaminated process gasesall while optimizing power consumption based on process needs (from 2 kW to 75 kW).

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vacuum Pumps Category

Diaphragm Type Vacuum Pumps

Application : Laboratory, Filtration, Medical, Chemical Processing

Condition : New

Dimension (L*W*H) : 210 x 150 x 210 mm

Power Mode : Electric

Accessories : Vacuum Gauge, Rubber Feet, Power Cable

Material : Other, Aluminum Alloy and Engineering Plastic

Water Ring Vacuum Pump

Application : Industrial vacuum generation, Filtration, Evacuation of air and gases, Chemical plants, Pharmaceuticals, Food processing

Condition : New

Dimension (L*W*H) : Depends on Model; Example: 900mm x 400mm x 650mm

Power Mode : Electric

Accessories : Inlet and Outlet Connections, Base Plate, Sealing Gaskets

Material : Other, Cast Iron / Stainless Steel

Solvent Recovery Unit

Application : Solvent purification and distillation in chemical, pharmaceutical, and paint industries

Condition : New

Dimension (L*W*H) : 1200 mm x 850 mm x 2000 mm

Power Mode : Electric

Accessories : Condenser, receiving tank, control panel

Material : Other, Stainless Steel

Solvent Recovery Plant

Application : Industrial solvent recovery, chemical, pharmaceutical, paint, ink, and coating industries

Condition : New

Dimension (L*W*H) : 3300 mm x 1800 mm x 2200 mm

Power Mode : Electric

Accessories : Condenser, Reboiler, Transfer Pumps, Storage Tanks, Control Panel

Material : Other, Stainless Steel

Unit No.1

Plot No. 7, Udyog Nagar, S.V.Road,

Goregaon (West), Mumbai-400 062.

Maharashtra. INDIA

Phone : 28740513

Unit No. 2

Plot No. A-316, Wagle Industrial Estate,

Road No. 22 Thane-400 604.

Maharashtra. INDIA

Tele : 25821773

Telefax : 25828006

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry