Solvent Recovery System

Solvent Recovery System Specification

- Material

- Stainless Steel

- Processing Type

- Batch / Continuous

- Condition

- New

- Technology

- Distillation, Condensation

- Dimension (L*W*H)

- 1200mm x 800mm x 1800mm

- Power Mode

- Electric

- Voltage

- 220V/380V AC

- Pressure Output

- Up to 2 Bar

- WorkingSpeed

- Up to 100 L/hr (depending on model)

- Application

- Solvent Recycling, Chemical Processing, Pharmaceutical, Paint, Ink Industries

- Coating Type

- Polished SS Surface

- Accessories

- Condensing Unit, Storage Tank, Vacuum Pump, Safety Valve

Solvent Recovery System Trade Information

- Delivery Time

- Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Certifications

- No

About Solvent Recovery System

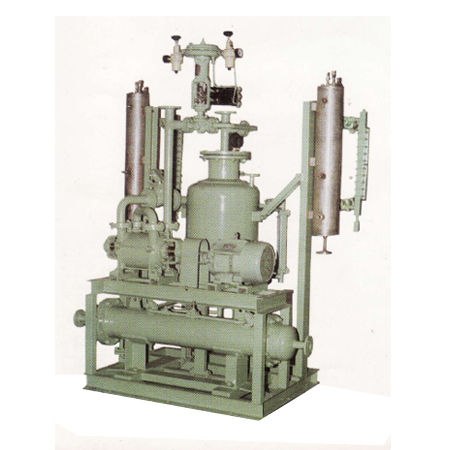

Solvent Recovery Systems

Customers need being our prime importance we manufacture, export and supply an exquisite array of Solvent Recovery System. The recovery system is sturdily & compactly engineered, light weighted and free of vibration with simple gear locking arrangement for boosters. Solvent Recovery System is used for fractional distillation, solvent recovery, vacuum drying & coating and oil drying. Manufactured using high grade quality material this system can be availed at affordable prices by our esteemed clients across the globe.

Further Details:

Pumpset : MB-43 Booster backed by JEBIVAK Liquid ring Vacuum pump model JVD-20 complete with cooling and recirculation arrangement

Duty : 1000 M3/Hr. at 15 Torr

Application : Fractional Distillation and Solvent Recovery .

FEATURES

-

High volumetric efficiency.

-

Low operating cost due to elimination of consumables and reduced pump-down time.

-

High reliability cause of precise machining assembly and vibration free rotation by dynamically balanced lobes & impellers.

-

Compact ,light, weight,robust, construction with quick and smooth operation.

-

Simple gear locking arrangement for boosters.

APPLICATIONS

-

Vacuum Furnaceos

-

Oil drying and degassing

-

Vacuum Drying/Freez Derying

-

Vacuum coating( metallising)

-

lmpregnation(transformer/capacitor s)

-

Vacuum Distillation

-

Vacuum Packaging Space Simulation

High-Efficiency Solvent Recovery

Achieve up to 98% recovery with advanced distillation and condensation technology. The system supports working speeds up to 100 L/hr, catering to diverse processing demands. Suitable for both batch and continuous operations, it delivers seamless results across paint, ink, pharmaceutical, and chemical industries.

Comprehensive Safety and Control

Safety is prioritized with features like automatic shutdown, overheat protection, and leak detection. Operators can choose between digital and manual control panels, ensuring both precision and flexibility. Designed to operate quietly (below 72 dB), the system minimizes workplace disturbances.

Customizable and User-Friendly Design

With tank capacities of 50L, 100L, and 200Lplus custom optionsthe unit adapts to specific requirements. Its stainless steel, polished finish ensures durability and easy maintenance, while the mobile frame allows relocation within your facility. Onsite installation support is available to streamline setup.

FAQs of Solvent Recovery System:

Q: How does the Solvent Recovery System achieve high recovery efficiency?

A: The system utilizes advanced distillation and condensation technologies, enabling it to recover up to 98% of solvents. Automated controls ensure precise temperature regulation (room temperature to 200C), maximizing efficiency during batch or continuous operations.Q: What safety features are integrated into the system?

A: Key safety features include automatic shutdown, overheat protection, and a leak detector. These systems are continuously monitored to minimize risks during operation, while the cooling systemeither water or air cooledmaintains safe working temperatures.Q: When is onsite installation support available?

A: Onsite installation support is offered for every system purchase. Qualified technicians will guide setup and initial operation at your facility, ensuring the system is installed correctly for optimal performance.Q: Where is the Solvent Recovery System primarily used?

A: This system is ideal for industries involved in solvent recycling and chemical processing, including pharmaceuticals, paint, and ink manufacturing. Its robust construction and adaptable features make it suitable for various industrial environments.Q: What is the process for solvent recovery within the unit?

A: Solvent recovery involves heating contaminated solvents inside the stainless steel tank, vaporizing them, and then condensing the pure solvent through cooling units. Collected solvent is stored in dedicated tanks, ready for reuse or further processing.Q: How does the digital/manual control panel benefit system operation?

A: The dual control panel provides flexibility; operators can select precise digital settings for accuracy or utilize manual controls for traditional operation, suiting both new and experienced users.Q: What are the primary benefits of using this system?

A: Using the Solvent Recovery System significantly reduces operational costs by recycling valuable solvents, minimizes environmental impact, and improves safety through robust protective features and low noise output (below 72 dB).

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vacuum Pumps Category

Diaphragm Type Vacuum Pumps

Condition : New

Material : Other, Aluminum Alloy and Engineering Plastic

Technology : Other, Diaphragm Type

Equipment Type : Diaphragm Vacuum Pump

Processing Type : Other, Vacuum Pump

Water Ring Vacuum Pump

Condition : New

Material : Other, Cast Iron / Stainless Steel

Technology : Other, Water Ring (Liquid Ring)

Equipment Type : Vacuum Pump

Processing Type : Other, Automatic

Solvent Recovery Unit

Condition : New

Material : Other, Stainless Steel

Technology : Other, Distillation and condensation

Equipment Type : Automatic Solvent Recovery Unit

Processing Type : Other, Solvent Recovery

Solvent Recovery Equipment

Condition : New

Material : Other, Stainless steel carbon steel

Technology : Other, Distillation technology

Processing Type : Continuous processing, Other

Unit No.1

Plot No. 7, Udyog Nagar, S.V.Road,

Goregaon (West), Mumbai-400 062.

Maharashtra. INDIA

Phone : 28740513

Unit No. 2

Plot No. A-316, Wagle Industrial Estate,

Road No. 22 Thane-400 604.

Maharashtra. INDIA

Tele : 25821773

Telefax : 25828006

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry