Water Ring Vacuum Pump

Water Ring Vacuum Pump Specification

- Equipment Type

- Vacuum Pump

- Material

- Cast Iron / Stainless Steel

- Processing Type

- Automatic

- Condition

- New

- Technology

- Water Ring (Liquid Ring)

- Dimension (L*W*H)

- Depends on Model; Example: 900mm x 400mm x 650mm

- Power Mode

- Electric

- Voltage

- 220V/380V/415V (as per model)

- Power Consumption

- 2 HP to 25 HP

- Pressure Output

- Up to 710 mmHg

- Application

- Industrial vacuum generation, Filtration, Evacuation of air and gases, Chemical plants, Pharmaceuticals, Food processing

- Accessories

- Inlet and Outlet Connections, Base Plate, Sealing Gaskets

Water Ring Vacuum Pump Trade Information

- Payment Terms

- Others

- Delivery Time

- Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Certifications

- No

About Water Ring Vacuum Pump

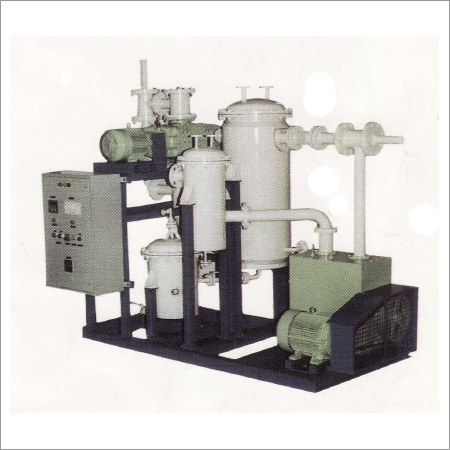

Water Ring Vacuum Pump

With excellent industrial experience we have gained reputation for manufacturing and exporting Water Ring Vacuum Pump. We analyze this vacuum pump on various parameters by following various vacuum standards by Indian Vacuum Society, in order to ensure quality and hassle free performance at clients end. Water Ring Vacuum Pump is widely used in various sectors like priming, crystallization, evaporating, filtration and low vacuum distillation. We provide long operational fluency, high durability, low power consumption and cost effective price of vacuum pump.

Technical Specifications:-

Capacity : 50 to 2550 M3/Hr.

-

Ult. Vacuum : 50 torr

Efficient Industrial Vacuum Generation

Designed for demanding industrial environments, this water ring vacuum pump is suitable for a variety of applications, including gas evacuation, filtration, and critical vacuum needs. Its automatic operation and durable build ensure continuous, dependable performance.

Versatility in Application and Power

Engineered with flexibility in mind, this vacuum pump handles a spectrum of voltages and power ratings, fitting seamlessly into different setups. Its a prime choice for chemical, pharmaceutical, and food processing industries that require adaptable and efficient vacuum solutions.

Ready-to-Install with Comprehensive Accessories

For maximum convenience, every unit comes complete with essential accessories like inlet and outlet connections, base plate, and sealing gaskets. This facilitates quick installation and startup, reducing downtime and optimizing operational efficiency.

FAQs of Water Ring Vacuum Pump:

Q: How does a water ring vacuum pump function in industrial applications?

A: A water ring vacuum pump operates by creating a liquid ring with water inside the casing, which traps and compresses gases or air, allowing efficient vacuum generation or air evacuation in processes such as chemical production, filtration, and pharmaceutical manufacturing.Q: What are the material options for this vacuum pump and how do they benefit specific industries?

A: These pumps are available in cast iron or stainless steel, offering corrosion resistance and durability. Stainless steel is ideal for food and pharmaceuticals due to its hygienic properties, while cast iron is suitable for general industrial use where robustness is essential.Q: When should an industrial vacuum pump be used in manufacturing processes?

A: An industrial vacuum pump is essential whenever air or gases need to be evacuated or a controlled vacuum is necessary, such as during filtering, drying, or transferring sensitive materials in chemical, pharmaceutical, or food processing sectors.Q: Where can this water ring vacuum pump be installed?

A: The pump can be installed in various industrial environments, including chemical plants, pharmaceutical production units, and food processing facilities. Its adaptable voltage and dimension options allow for customized installation based on spatial and operational requirements.Q: What are the steps involved in the operational process of this vacuum pump?

A: Operation involves connecting the inlet and outlet, securing the base plate, ensuring sealing gaskets are in place, connecting to the appropriate power supply, and initiating the automatic vacuum process as per your applications requirements.Q: What accessories are included with the vacuum pump?

A: Each pump comes with essential accessories such as inlet and outlet connections, a base plate for secure mounting, and sealing gaskets to ensure airtight operation, enabling ready installation and reliable use.Q: How does using this pump benefit industrial operations?

A: Utilizing this water ring vacuum pump enhances productivity by providing consistent vacuum performance, reducing downtime due to robust automatic operation, and offering long-term reliability with corrosion-resistant materials and user-friendly installation features.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vacuum Pumps Category

Oil Sealed High Vacuum Pumps

Condition : New

Material : Other, Cast Iron

Equipment Type : High Vacuum Pump

Processing Type : Other, Vacuum Pumping

Mechanical Booster Vacuum Systems

Condition : New

Material : Other, Mild Steel

Voltage : 380V 440V

Processing Type : Standard

Solvent Recovery Plant

Condition : New

Material : Other, Stainless Steel

Voltage : 415 V AC, 3 Phase, 50/60 Hz

Equipment Type : Solvent Recovery Plant

Processing Type : Other, Batch/Continuous

Liquid Ring Vacuum Pumping System

Condition : New

Material : Other, Stainless Steel / Cast Iron / Bronze (as per requirement)

Voltage : 220 V / 380 V / 415 V, 50 Hz / 60 Hz

Equipment Type : Vacuum Pumping System

Processing Type : Other, Vacuum Generation

Unit No.1

Plot No. 7, Udyog Nagar, S.V.Road,

Goregaon (West), Mumbai-400 062.

Maharashtra. INDIA

Phone : 28740513

Unit No. 2

Plot No. A-316, Wagle Industrial Estate,

Road No. 22 Thane-400 604.

Maharashtra. INDIA

Tele : 25821773

Telefax : 25828006

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry