Monoblock Water Ring Vacuum Pumps

Monoblock Water Ring Vacuum Pumps Specification

- Equipment Type

- Vacuum Pump

- Material

- Cast Iron

- Processing Type

- Monoblock

- Condition

- New

- Technology

- Water Ring Vacuum Pump

- Dimension (L*W*H)

- Varies by Model

- Power Mode

- Electric

- Voltage

- 220/380 V

- Power Consumption

- 0.75 kW to 5.5 kW

- Pressure Output

- Up to 700 mm Hg

- Application

- Industrial Vacuum, Liquid Transfer, Evacuation Processes

- Accessories

- Standard Fittings Coupled Motor

Monoblock Water Ring Vacuum Pumps Trade Information

- Payment Terms

- Others

- Delivery Time

- Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Certifications

- No

About Monoblock Water Ring Vacuum Pumps

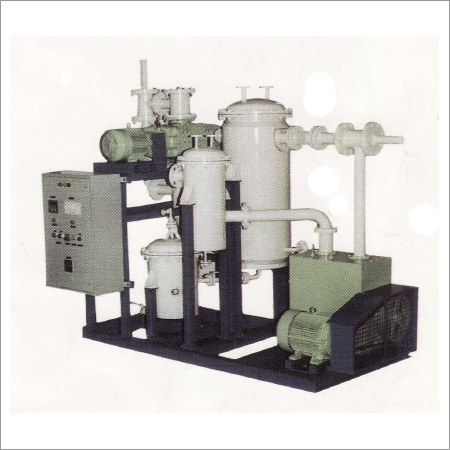

Monoblock Water Ring Vacuum Pumps

In the voyage of more than 2 decades we have gained successful reputation as a manufacturer, exporter and supplier of Monoblock Water Ring Vacuum Pumps. The whole array of vacuum pumps are stringently tested on various parameters defined by the vacuum society. Monoblock Water Ring Vacuum Pumps find its applications in low-capacity requirements of filtration, distillation and priming. The range of vacuum pumps can be customized as per the requirement of our valued customers. These affordable vacuum pumps are easy to maintain & install and ensure high operational efficacy.

Technical Specifications:-

Capacity : 15 & 25 M3/Hr

-

Vacuum : 60 torr

Versatile Industrial Applications

These monoblock water ring vacuum pumps are tailored for versatile use across various industrial scenarios. Whether used for vacuum generation, liquid transfer, or evacuation processes, they deliver reliable performance. Their robust design ensures suitability for round-the-clock operations in manufacturing plants, laboratories, or process industries.

Efficient and Low Maintenance Design

Thanks to their direct coupled motor mounting and mechanical sealing, these pumps operate smoothly while requiring minimal maintenance. The heavy-duty cast iron construction and smooth painted finish enhance durability, while the low noise output ensures a more comfortable working environment.

FAQs of Monoblock Water Ring Vacuum Pumps:

Q: How do monoblock water ring vacuum pumps work in industrial applications?

A: These pumps use water ring technology to create a vacuum by forming a liquid ring inside the housing. This mechanism allows for efficient suction and transfer of gases or liquids in processes such as vacuum generation and evacuation tasks.Q: What are the benefits of choosing a monoblock water ring vacuum pump over traditional models?

A: Monoblock water ring vacuum pumps offer compactness, easier installation, low noise levels, and reduced maintenance due to their integrated design with direct coupled motors and mechanical sealing, making them highly efficient and reliable.Q: When is it recommended to use a three-phase over a single-phase pump?

A: Three-phase pumps are preferable for larger-scale industrial operations requiring higher flow rates and suction capacities, providing more efficient and consistent power delivery compared to single-phase units.Q: Where can these vacuum pumps be installed?

A: These units are base-mounted, making them suitable for installation on stable platforms in industrial settings such as factories, laboratories, or process facilities. Their robust, heavy-duty construction supports safe and secure placement.Q: What is the process for maintaining the monoblock vacuum pump?

A: Regular maintenance involves checking for wear on the mechanical seal, cleaning the painted exterior, monitoring for unusual noises, and ensuring the pump operates within specified voltage and power ranges to maximize lifespan.Q: How should these pumps be used for liquid transfer applications?

A: To use the pump for liquid transfer, ensure the appropriate fittings are connected securely, select the correct voltage based on your power supply, and follow the manufacturers guidelines for operation to achieve optimum suction and discharge performance.Q: What are the main advantages of its heavy-duty cast iron construction?

A: Cast iron construction provides enhanced durability, corrosion resistance, and stability under industrial operating conditions, ensuring a longer operational life and reduced risk of mechanical failure.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vacuum Pumps Category

Oil Sealed Vacuum Pumps

Condition : New

Voltage : 220V / 415V

Material : Other, Cast Iron / Mild Steel

Power Mode : Electric

Application : Laboratory, Industrial Vacuum Process, Distillation, Filtration, Dehydration

Processing Type : Standard

Water Ring Vacuum Pump

Condition : New

Voltage : 220V/380V/415V (as per model)

Material : Other, Cast Iron / Stainless Steel

Power Mode : Electric

Application : Industrial vacuum generation, Filtration, Evacuation of air and gases, Chemical plants, Pharmaceuticals, Food processing

Processing Type : Other, Automatic

Mechanical Booster Vacuum Systems

Condition : New

Voltage : 380V 440V

Material : Other, Mild Steel

Power Mode : Electric

Application : Industrial, Chemical, Pharmaceutical, Food Processing, Vacuum Drying, Distillation, Dehydration

Processing Type : Standard

Liquid Ring Vacuum Pumping System

Condition : New

Voltage : 220 V / 380 V / 415 V, 50 Hz / 60 Hz

Material : Other, Stainless Steel / Cast Iron / Bronze (as per requirement)

Power Mode : Electric

Application : Chemical, Pharmaceutical, Food Processing, Power Generation, Petrochemical, Distillation, Evacuation, Filtration

Processing Type : Other, Vacuum Generation

Unit No.1

Plot No. 7, Udyog Nagar, S.V.Road,

Goregaon (West), Mumbai-400 062.

Maharashtra. INDIA

Phone : 28740513

Unit No. 2

Plot No. A-316, Wagle Industrial Estate,

Road No. 22 Thane-400 604.

Maharashtra. INDIA

Tele : 25821773

Telefax : 25828006

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry