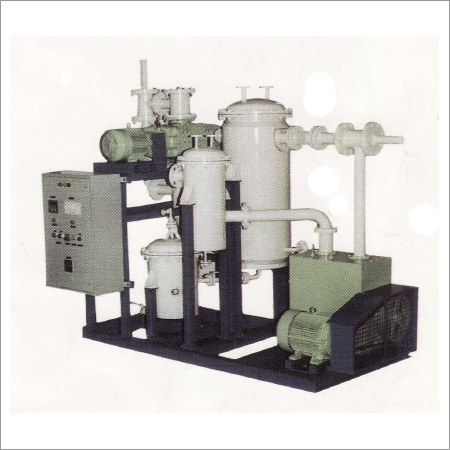

Solvent Recovery Unit

Solvent Recovery Unit Specification

- Equipment Type

- Automatic Solvent Recovery Unit

- Material

- Stainless Steel

- Processing Type

- Solvent Recovery

- Condition

- New

- Technology

- Distillation and condensation

- Dimension (L*W*H)

- 1200 mm x 850 mm x 2000 mm

- Power Mode

- Electric

- Voltage

- 220V / 380V, 50 Hz

- Pressure Output

- Atmospheric or slight vacuum

- Application

- Solvent purification and distillation in chemical, pharmaceutical, and paint industries

- Accessories

- Condenser, receiving tank, control panel

Solvent Recovery Unit Trade Information

- Payment Terms

- Others

- Delivery Time

- Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Certifications

- No

About Solvent Recovery Unit

Solvent Recovery Unit

We serve a vast market area of pharma, chemical and plastic by manufacturing and exporting exclusive and quality assortment of Solvent Recover Unit. This recovery unit pumps out the dry HCl from oil drying, vacuum coating and vacuum distillation. Solvent Recovery Unit ensures high volumetric vibration free efficiency, accelerated & smooth operation and high reliability. The entire range of recovery units is as per the international quality standards. Further, we avail our range of recovery unit at reasonable cost.

Further Details:

Pumpset : JEBIVAK Liquid ring Compressor model JVC-20 with double mechanical seals, flushing arrangement as per API Plan 52 and seal liquid recirculation arrangement .

Duty : 50 NM3/Hr. At 3.5 Torr

Application : Pumping of dry Hcl gas.

FEATURES

-

High volumetric efficiency.

-

Low operating cost due to elimination of consumables and reduced pump-down time.

-

High reliability cause of precise machining assembly and vibration free rotation by dynamically balanced lobes & impellers.

-

Compact ,light, weight,robust, construction with quick and smooth operation.

-

Simple gear locking arrangement for boosters.

APPLICATIONS

-

Vacuum Furnaceos

-

Oil drying and degassing

-

Vacuum Drying/Freez Derying

-

Vacuum coating( metallising)

-

lmpregnation(transformer/capacitor s)

-

Vacuum Distillation

-

Vacuum Packaging Space Simulation

Advanced Control and Safety

This solvent recovery unit features a PLC-controlled system with an intuitive HMI interface for precise operation and monitoring. Safety is prioritized through advanced protection mechanisms including overheat alarms, leakage sensors, and a readily accessible emergency stop, ensuring reliable and secure performance even during continuous, automated use.

Comprehensive Skid-Mounted Design

Engineered for plug-and-play convenience, the unit comes skid-mounted, simplifying installation and relocation. Its robust stainless steel construction guarantees durability in industrial environments. All necessary accessories, such as the condenser, receiving tank, and control panel, are integrated, minimizing installation time and maximizing operational readiness.

Efficient Distillation and Condensation Process

Utilizing an electric heater and water-cooled condenser, the system excels in solvent recovery through precise distillation and condensation. Suitable for atmospheric or slight vacuum pressure, the process delivers high purity outputs, supporting sustainable industrial practices by enabling solvent reuse while effectively reducing waste costs.

FAQs of Solvent Recovery Unit:

Q: How does the Automatic Solvent Recovery Unit operate in industrial environments?

A: The unit uses electric heating and water-cooled condensation to distill and recover solvents. It is equipped with PLC and HMI controls for easy operation and precise monitoring, suitable for continuous use in chemical, pharmaceutical, and paint industries.Q: What safety features are included in the solvent recovery unit?

A: Safety is ensured through overheat protection, leakage detection sensors, and an emergency stop button. These features help prevent accidents or equipment damage during operation, providing peace of mind for operators.Q: When should the solvent recovery process be performed?

A: The recovery process should be initiated whenever spent solvents need to be purified for reuse or disposal. This is commonly done after production shifts or at intervals determined by the workload and solvent usage patterns in the facility.Q: Where is the unit typically installed, and what are its installation requirements?

A: As a skid-mounted system, the unit can be installed easily on flat surfaces within production areas or solvent processing rooms. It requires an electrical connection (220V/380V, 50 Hz), water supply for cooling, and should be placed in a well-ventilated location.Q: What applications is this solvent recovery unit best suited for?

A: This equipment is ideal for solvent purification in chemical, pharmaceutical, and paint manufacturing sectors. Its engineered for processes involving distillation and condensation where solvent recycling is essential.Q: How do users benefit from using this solvent recovery unit?

A: Users benefit by significantly reducing solvent purchasing and disposal costs. The system enables recycling of high-purity solvents, minimizes environmental impact, and supports compliance with industry regulations.Q: What distinguishes this solvent recovery unit from traditional models?

A: Distinctive features include automatic PLC control with an HMI interface, robust skid-mounted design for ease of installation, comprehensive safety systems, and efficient recovery at temperatures up to 180C, all constructed in durable stainless steel.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vacuum Pumps Category

Oil Sealed High Vacuum Pump

Minimum Order Quantity : 1 Nos

Material : Other, Cast Iron

Condition : New

Power Mode : Electric

Processing Type : Other, Vacuum Generation

Technology : Other, Oil Sealed Rotary Vane

Vacuum System

Material : Other, Stainless Steel

Condition : New

Power Mode : Electric

Processing Type : Other, Automatic

Technology : Other, Vacuum Pump Driven System

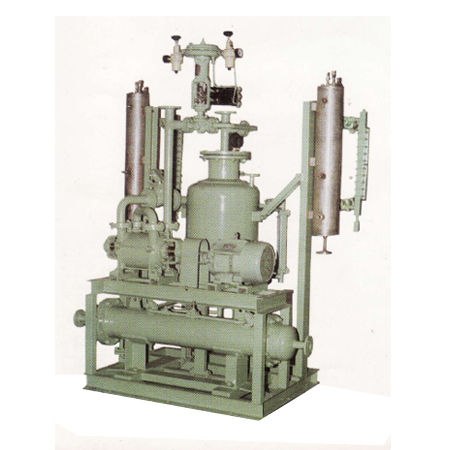

Mechanical Booster Vacuum Systems

Material : Other, Mild Steel

Condition : New

Power Mode : Electric

Processing Type : Standard

Liquid Ring Vacuum Pumping System

Material : Other, Stainless Steel / Cast Iron / Bronze (as per requirement)

Condition : New

Power Mode : Electric

Processing Type : Other, Vacuum Generation

Technology : Other, Liquid Ring

Unit No.1

Plot No. 7, Udyog Nagar, S.V.Road,

Goregaon (West), Mumbai-400 062.

Maharashtra. INDIA

Phone : 28740513

Unit No. 2

Plot No. A-316, Wagle Industrial Estate,

Road No. 22 Thane-400 604.

Maharashtra. INDIA

Tele : 25821773

Telefax : 25828006

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry