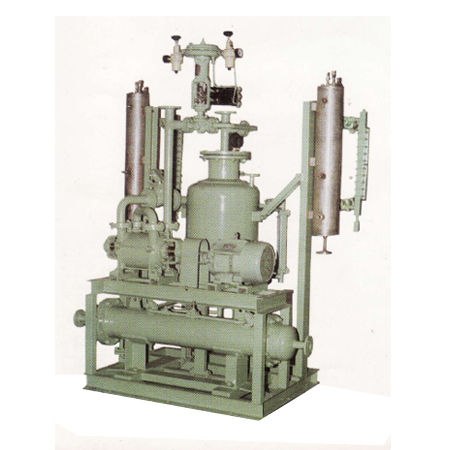

Water Ring Vaccum Pumps

Water Ring Vaccum Pumps Specification

- Usage

- Industrial

- Equipment Type

- Water Ring Vaccum Pumps

- Material

- Iron

- Processing Type

- Customized

- Condition

- New

- Color

- Blue

- Voltage

- 220-240 Volt (v)

- Warranty

- 1 Year

About Water Ring Vaccum Pumps

Water Ring Vaccum Pumps

26 years of efficient work has led us to the extreme level recognition in the field of manufacturing exporting and supplying Water Ring Vacuum Pumps Capable of bearing withstanding heavy load of water vapors this vacuum pump is extensively used in distillation filtration vacuum drying and water extraction from paper cloth Water Ring Vacuum Pumps are accredited at global level due to its sturdy construction noiseless running and oil free compressed air The pump is available at affordable prices

Further Details

JEBIVAK Waterring pumps are basically liquidring pumps Since water being very commonly used as the sealing liquidthese are called as Waterring pumps These pumps are specially designed for handling gases damp media or moist air and even corrosive vapours by proper selection of material of construction The pumps can be driven by direct drive or Vbelt drive arrangement with Electric Motors or Diesel Engines

JEBIVAK pumps are built up with high accuracy and close tolerances to give best performance The construction is robust but simple and consisting of very few components Dismantling and assembling of the pump is therefore very easy The major components are casing impeller and control discs The material of these components are chosen depending on the application Standard supply is with casing in Cast Iron and impeller and control discs in dynamically balanced to maximum accuracy and it rotates on roller bearing at both the ends The running is therefore smooth and the vibration free It is assembled eccentrically in the casing having control discs on sides Standard pumps are supplied with glandpack arrangement however mechanical seals aslo can be provided whenever necessary

Generally the pumps are silent except very little humming noise at the exhaust This humming noise also can be reduced by using a silencer in the discharge line A general layout is shown on the next page It is advisable to use a non return valve in the suction line which prevents backflow of liquid in case of stoppage of pump under vacuum Pump creates rattling noise in the final range of vacuum due to cavitation A ventcock is provided on the side casingcover to leak in air and reduce cavitation noise Ultimate vacuum attainable by the pumps depend on the ringliquid temperature and barometric pressure It is 710mm of Hg with ringliquid as water at 30oC having 08 to 10 Kgcm2 pressure and barometer at 760mm of Hg

This pump can also be used as a Compressor by using a liquid separator in the discharge line The compressed air available is little moist but clean and oilfree Maximum attainable pressure is 18 Kgcm2 A general layout of compressor is as shown on the next page

Advantages and Applications

Sturdy construction and long life smooth running with low noise and free from vibrations capable of handling heawy amount of watervapours compressed air totally oilfree Easy for maintenance

Suitable for

Distillation filtration vacuum drying water extraction from paper and cloth evaporation crystallisation sizing for PVC pipes priming of centrifugal pumps brake testing etc

Model

Motor HP For

Pump Speed R P M

Capacity at Open Suction

Sealing Liquid LPM

Size in MM

Inch

Vacuum Pump

Compressor

CFM

M3Hr

A

B

C

D

E

F

G

H

J

WR 30

35

5

2880

30

51

6

315

163

132

290

135

256

25

670

WR 50

5

75

2880

50

85

9

395

227

132

290

132

250

40

795

WR 75

75

10

2880

75

128

14

410

231

132

290

132

250

40

830

WR 100

75

125

1440

100

170

16

648

369

212

445

200

380

60

1128

WR 130

10

15

1440

130

220

18

673

374

212

445

200

380

60

1193

WR 150

125

20

1440

150

255

20

683

384

212

445

200

380

60

1298

WR 200

15

20

1440

200

340

30

802

458

260

555

235

430

80

1422

WR 260

20

25

1440

260

442

35

874

495

260

555

235

430

80

1543

WR 300

25

30

1440

300

510

40

883

498

260

555

235

430

80

1558

WR 430

30

40

960

430

725

60

912

510

324

660

290

540

125

1670

WR 500

30

40

960

500

850

75

948

524

324

660

290

540

125

1800

WR 650

40

50

960

650

1105

80

1048

574

324

660

290

540

125

1900

WR 900

75

100

725

900

1530

150

1172

660

415

860

380

800

200

2290

1

WR 1200

100

125

725

1200

2040

200

1360

740

415

860

380

800

200

2700

1

WR 1500

125

150

725

1500

2550

250

1510

815

415

860

380

800

200

3010

1

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vacuum Pumps Category

Vacuum System

Material : Other, Stainless Steel

Condition : New

Power Mode : Electric

Technology : Other, Vacuum Pump Driven System

Accessories : Vacuum Gauge, Valves, Fittings

Application : Industrial, Laboratory, Chemical, Pharmaceutical

Solvent Recovery Unit

Material : Other, Stainless Steel

Condition : New

Power Mode : Electric

Technology : Other, Distillation and condensation

Accessories : Condenser, receiving tank, control panel

Application : Solvent purification and distillation in chemical, pharmaceutical, and paint industries

Solvent Recovery Plant

Material : Other, Stainless Steel

Condition : New

Power Mode : Electric

Technology : Other, Distillation/Condensation

Accessories : Condenser, Reboiler, Transfer Pumps, Storage Tanks, Control Panel

Application : Industrial solvent recovery, chemical, pharmaceutical, paint, ink, and coating industries

Solvent Recovery Equipment

Material : Other, Stainless Steel

Condition : New

Power Mode : Electric

Technology : Other, Distillation / Condensation

Accessories : Condensation Unit, Collection Vessels, Control Panel

Application : Industrial solvent recovery, chemical, pharmaceutical, and paint industries

Unit No.1

Plot No. 7, Udyog Nagar, S.V.Road,

Goregaon (West), Mumbai-400 062.

Maharashtra. INDIA

Phone : 28740513

Unit No. 2

Plot No. A-316, Wagle Industrial Estate,

Road No. 22 Thane-400 604.

Maharashtra. INDIA

Tele : 25821773

Telefax : 25828006

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry