Booster Vacuum Pump

Booster Vacuum Pump Specification

- Equipment Type

- Roots Booster Vacuum Pump

- Material

- Cast Iron

- Processing Type

- Automatic

- Condition

- New

- Technology

- Oil Sealed Rotary

- Dimension (L*W*H)

- Varies by Model

- Power Mode

- Electric

- Voltage

- 220V/380V, 3 Phase

- Power Consumption

- Depends on Model (typically from 2 to 15 HP)

- WorkingSpeed

- Up to 2880 RPM

- Application

- Industrial Vacuum Process, Pharmaceutical, Food Packaging, Chemical, Plastic, Laboratory

- Accessories

- Standard Accessories Included

Booster Vacuum Pump Trade Information

- Payment Terms

- Others

- Delivery Time

- Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Certifications

- No

About Booster Vacuum Pump

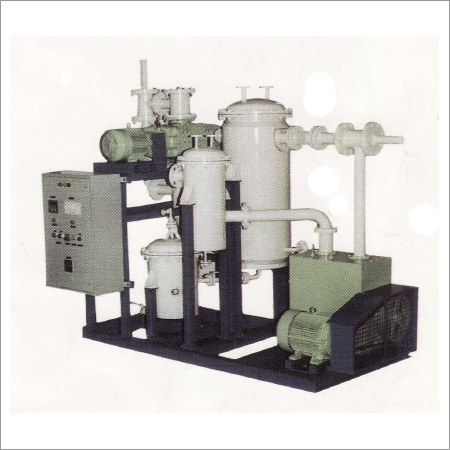

Booster Vacuum Pump

We are distinguished by our policy of never compromising on quality aspect of manufacturing and exporting Booster Vacuum Pump. Available in different specifications, these vacuum systems find wide usage in chemical, pharmaceuticals, electrical and plastic industries. Best in quality and high in standards, this Booster Vacuum Pump is highly acknowledge by our clients of country and Middle East Gulf countries. Sturdy in construction, high in efficiency and low in oil consumption, this system is available at market leading prices.

High-Efficiency Oil-Sealed Rotary Technology

This Roots Booster Vacuum Pump employs advanced oil-sealed rotary mechanisms, guaranteeing consistent vacuum generation in industrial applications. Designed for high throughput, the unit offers robust performance and reliability, making it ideal for pharmaceutical, chemical, food, and laboratory industries. Automatic operation ensures ease of use and minimal maintenance.

Versatile Applications Across Industries

Our vacuum pump supports a broad spectrum of applicationsranging from laboratory analysis to large-scale chemical and plastic processing. Suitable for food packaging and pharmaceutical operations, it provides clean, stable vacuum environments needed for sensitive processes and precision work.

Tailored to Your Operational Needs

With electric power modes and models ranging from 2 to 15 HP, our vacuum pumps can be customized for diverse operational requirements. Options for 220V or 380V (3-phase) systems accommodate various installation environments, ensuring seamless integration into your workflow.

FAQs of Booster Vacuum Pump:

Q: How does a Roots Booster Vacuum Pump function in industrial vacuum processes?

A: A Roots Booster Vacuum Pump increases vacuum efficiency by operating as a secondary stage after a primary pump. Its oil-sealed rotary design rapidly boosts the vacuum level, enabling quicker evacuation and higher capacity needed for industrial applications such as food, chemical, and pharmaceutical processing.Q: What are the benefits of using cast iron for the pumps construction?

A: Cast iron construction imparts durability and resistance to wear, making the pump suitable for rigorous industrial usage. It also reduces vibration and noise, ensuring long-lasting performance with minimal maintenance.Q: When should I opt for an oil-sealed rotary vacuum pump over other types?

A: Oil-sealed rotary pumps are ideal when a deep and stable vacuum is required, as in pharmaceuticals, plastics, laboratories, and food packaging. Their superior sealing helps achieve higher vacuum levels and consistent performance in demanding environments.Q: Where can this Roots Booster Vacuum Pump be installed?

A: These pumps are designed for flexibility and can be installed in a wide range of industrial settings, including laboratories, manufacturing facilities, and processing plants. The varying dimensions and voltage options allow easy integration into both small and large operations.Q: What is the process for integrating the vacuum pump into an existing production line?

A: Installation involves connecting the pump to your power supply (220V/380V, 3-phase) and integrating it with the vacuum line of your production setup. Our pumps come with standard accessories, streamlining the installation and commissioning process. Professional guidance is available for optimal setup.Q: How should the Roots Booster Vacuum Pump be used for best performance?

A: For optimal performance, operate the pump within its specified speed (up to 2880 RPM) and power range. Ensure regular oil maintenance and monitor operational parameters as recommended in the manual. Automatic control simplifies usage, reducing manual intervention and downtime.Q: What advantages does this equipment provide for exporters and suppliers in India?

A: This pump offers reliable performance in diverse environments, ensuring consistent vacuum for export-quality production standards. Its robust build and adaptable power options make it an ideal choice for manufacturers and suppliers aiming to meet both domestic and international demands with efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vacuum Pumps Category

Oil Sealed High Vacuum Pump

Power Mode : Electric

Application : Laboratory, Industrial, Research, Pharmaceutical, Chemical Processing

Material : Other, Cast Iron

Dimension (L*W*H) : Varies by Model (e.g., 450 x 180 x 250 mm)

Condition : New

Pressure Output : Up to 0.05 mbar

Oil Sealed High Vacuum Pumps

Power Mode : Electric

Application : Industrial, Laboratory, Pharmaceutical, Chemical and Food Processing

Material : Other, Cast Iron

Dimension (L*W*H) : Varies By Model

Condition : New

Pressure Output : Up to 0.05 mm Hg (50 Microns)

Monoblock Water Ring Vacuum Pumps

Power Mode : Electric

Application : Industrial Vacuum, Liquid Transfer, Evacuation Processes

Material : Other, Cast Iron

Dimension (L*W*H) : Varies by Model

Condition : New

Pressure Output : Up to 700 mm Hg

Mechanical Booster Vacuum Systems

Power Mode : Electric

Application : Industrial, Chemical, Pharmaceutical, Food Processing, Vacuum Drying, Distillation, Dehydration

Material : Other, Mild Steel

Dimension (L*W*H) : Customizable as per requirement

Condition : New

Pressure Output : Up to 0.001 mbar

Unit No.1

Plot No. 7, Udyog Nagar, S.V.Road,

Goregaon (West), Mumbai-400 062.

Maharashtra. INDIA

Phone : 28740513

Unit No. 2

Plot No. A-316, Wagle Industrial Estate,

Road No. 22 Thane-400 604.

Maharashtra. INDIA

Tele : 25821773

Telefax : 25828006

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry