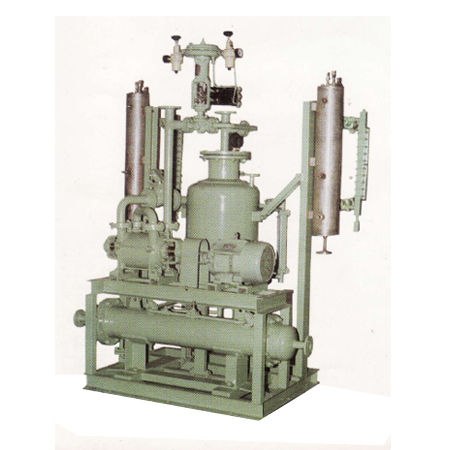

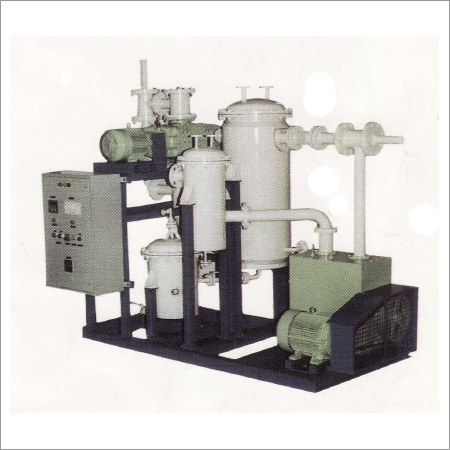

Mechanical Booster Vacuum Systems

Mechanical Booster Vacuum Systems Specification

- Material

- Mild Steel

- Processing Type

- Standard

- Condition

- New

- Dimension (L*W*H)

- Customizable as per requirement

- Power Mode

- Electric

- Voltage

- 380V 440V

- Power Consumption

- As per capacity (varies with model)

- Pressure Output

- Up to 0.001 mbar

- Application

- Industrial, Chemical, Pharmaceutical, Food Processing, Vacuum Drying, Distillation, Dehydration

- Coating Type

- Powder Coated

- Accessories

- Control Panel, Valves, Interconnecting Pipelines, Silencers

Mechanical Booster Vacuum Systems Trade Information

- Payment Terms

- Others

- Delivery Time

- Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Certifications

- No

About Mechanical Booster Vacuum Systems

Mechanical Booster Vacuum Systems

Squad of highly savoir-faire professionals helps us to meet the need of our global patrons in appropriate manner by manufacturing and exporting Mechanical Booster Vacuum Systems. Owing to the features like robust construction, impeccable performance and long operational efficiency they find vast applications in various industries like pharmacy, electrical, chemical and plastics. Mechanical Booster Vacuum Systems offered by us are qualitatively approved by Indian Vacuum Society and thus highly accredited by our national & international clients. The exclusive range of vacuum system is available at affordable prices.

Further Details:

Pumpset : MB-53 Booster backed by JEBIVAK Oil Sealed Rotary vane vacuum pump model Y-24 of Capacity 450 M3/Hr

Duty : 2100 M3/Hr. at 0.1 Torr

Application : Transformer Drying

Versatile Industrial Applications

These booster vacuum systems are tailored for demanding processes such as distillation, dehydration, and vacuum drying. Their compatibility with multiple base pumps and adaptability to both chemical and pharmaceutical environments make them a valuable asset across diverse industries. Users benefit from enhanced process control and operational reliability.

Efficient Operation and Control

Equipped with either fully automatic or manual control systems, these vacuum boosters simplify integration into modern factory setups. The systems are engineered for user comfort, combining low noise levels and effective splash lubrication to ensure seamless, low-maintenance operation.

FAQs of Mechanical Booster Vacuum Systems:

Q: How can a mechanical booster vacuum system improve vacuum processes in industrial applications?

A: By increasing the overall pumping speed and reducing ultimate pressure, mechanical booster vacuum systems significantly enhance vacuum efficiency. This leads to faster processing, energy savings, and better quality control in operations such as drying, distillation, and dehydration.Q: What are the available drive and motor options for these vacuum systems?

A: You can choose between direct coupled or belt-driven configurations, with motor power options ranging from 3 HP to 30 HP. This flexibility ensures that different application requirements and energy capacities can be met efficiently.Q: When is it necessary to use double booster stages instead of a single stage?

A: Double booster stages are recommended for applications requiring deeper vacuum levels or higher pumping speeds. They help achieve lower pressures more efficiently when compared to single-stage systems, making them suitable for intensive industrial or chemical processing tasks.Q: Where can these vacuum systems be installed, and how are they mounted?

A: The systems are designed for floor mounting on skids and are customizable to fit various industrial layouts. Their robust construction ensures stability and ease of installation in settings ranging from pharmaceutical plants to food processing factories.Q: What is the process for controlling and maintaining these vacuum boosters?

A: Control can be handled automatically or manually via an integrated control panel, depending on user preference. Maintenance is streamlined due to the splash lubrication system and accessible design, with periodic inspection and lubricant checks ensuring long-term reliability.Q: Which base vacuum pumps are compatible with these mechanical booster systems?

A: These systems are compatible with rotary vane, water ring, and oil-sealed base vacuum pumps, providing flexibility to match various existing setups and optimizing performance according to specific process needs.Q: What are the primary benefits of selecting this mechanical booster vacuum system?

A: Key benefits include high pumping speeds, low noise levels, robust construction, efficient cooling, and ease of integration. Their versatile design supports a wide range of applications, maximizes uptime, and offers customizable dimensions and accessories to meet individual project specifications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vacuum Pumps Category

Water Ring Vacuum Pump

Power Mode : Electric

Condition : New

Voltage : 220V/380V/415V (as per model)

Technology : Other, Water Ring (Liquid Ring)

Accessories : Inlet and Outlet Connections, Base Plate, Sealing Gaskets

Material : Other, Cast Iron / Stainless Steel

Monoblock Water Ring Vacuum Pumps

Power Mode : Electric

Condition : New

Voltage : 220/380 V

Technology : Other, Water Ring Vacuum Pump

Accessories : Standard Fittings Coupled Motor

Material : Other, Cast Iron

Solvent Recovery Unit

Power Mode : Electric

Condition : New

Voltage : 220V / 380V, 50 Hz

Technology : Other, Distillation and condensation

Accessories : Condenser, receiving tank, control panel

Material : Other, Stainless Steel

Solvent Recovery System

Power Mode : Electric

Condition : New

Voltage : 220V/380V AC

Technology : Other, Distillation, Condensation

Accessories : Condensing Unit, Storage Tank, Vacuum Pump, Safety Valve

Material : Other, Stainless Steel

Unit No.1

Plot No. 7, Udyog Nagar, S.V.Road,

Goregaon (West), Mumbai-400 062.

Maharashtra. INDIA

Phone : 28740513

Unit No. 2

Plot No. A-316, Wagle Industrial Estate,

Road No. 22 Thane-400 604.

Maharashtra. INDIA

Tele : 25821773

Telefax : 25828006

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry